Wind turbines are essential for achieving decarbonisation and increasing energy security. The UK plans to reach up to 50 GW of offshore wind deployment by 2030. This target is driving demand for the components and materials required to produce wind turbines, and technology metals such as rare earth elements (REEs) are playing a major role. REEs such as neodymium, praseodymium, dysprosium and terbium are used in the production of neodymium-iron-boron (NdFeB) permanent magnets, which are used to manufacture powerful generators that come in a range of technical configurations. At the same time, several installed wind turbines are expected to reach their decomissioning stage soon and could therefore provide a secondary source of REEs.

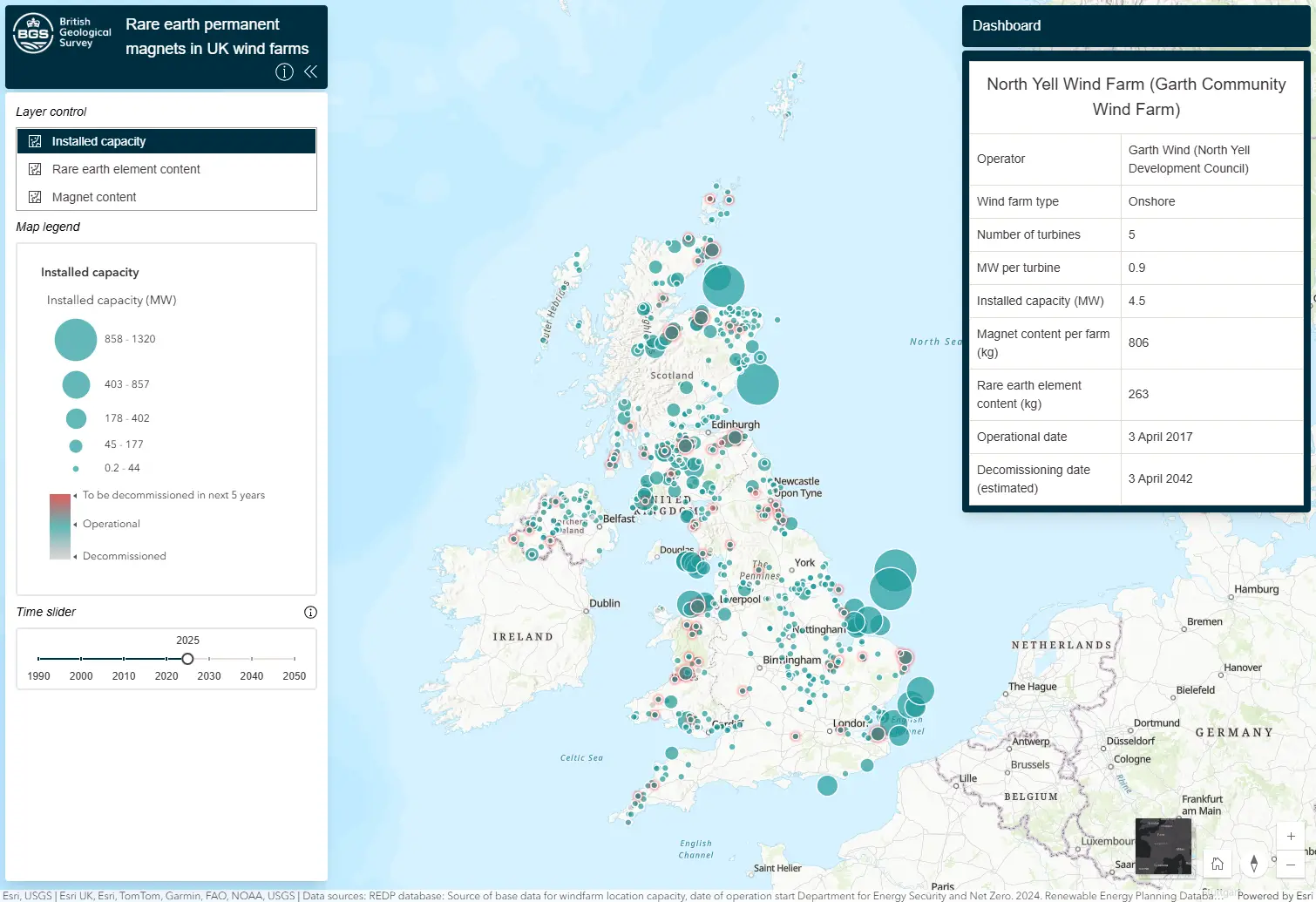

Interactive map of rare earth permanent magnets in UK wind farms

The UK has many on- and offshore wind farms, which contain various amounts of permanent magnets depending on the technology of the generator. This interactive map shows the UK wind farms with their installed capacity and estimated magnet and rare earth content. It also provides an estimate of when these wind turbines will be decommissioned and become available for reuse or recycling to boost the circular economy. Scroll through time, to see when the wind farms started operation and when they will reach their end-of-life.

Rare earth permanent magnets in UK wind farms map

Components and metals in wind turbines

Supply and demand

Based upon the National Grid Future Energy Strategy Report 2021 (National Grid, 2021) the most aggressive 'leading-the-way' scenario predicts an increase from currently 89 terawatt hours (TWh) to 645 TWh by 2050, which will require a significant inflow of the necessary materials and components.

Today's demand for wind turbines

Wind power accounted for 29 per cent of the UK's total electricity generation in 2021; 64 TWh came from wind turbines, with 29 TWh from onshore and 35 TWh from offshore.

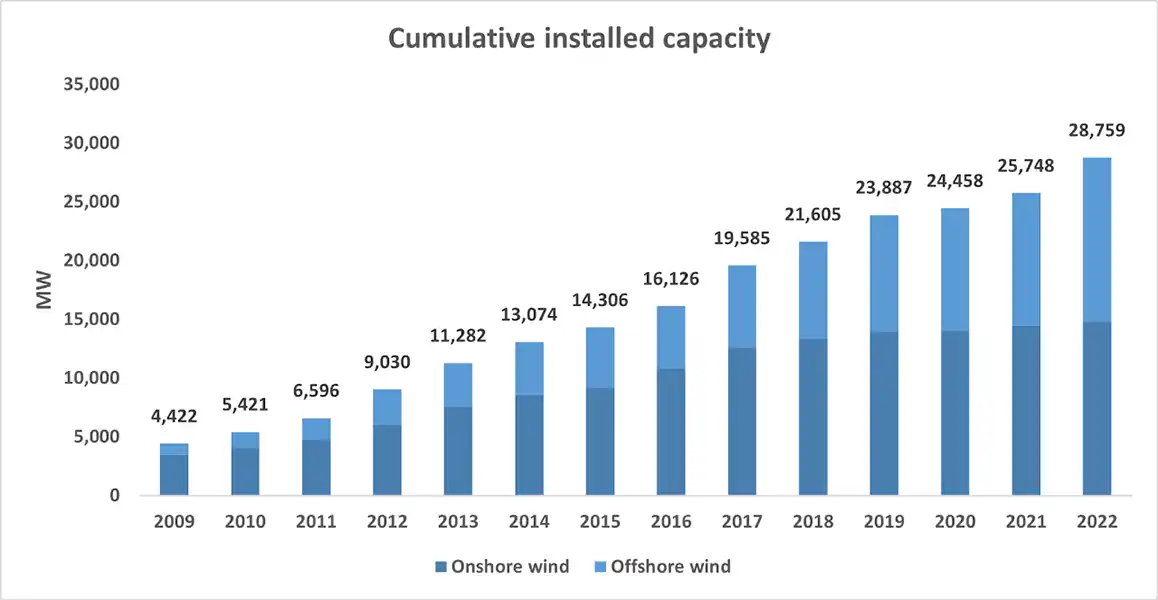

With total wind turbine generation power of 78 342 126 megawatt hours per year (MWh/pa), the current installed base of wind turbines amounts to 8873 onshore installations and 2652 offshore installations. Figure 2 is a map of UK operational wind farms with a capacity above 0.5 GW, whilst Figure 3 is an overview of the currently installed base and its development over time. In 2022, the cumulative installed capacity was 28 759 MW.

The installed base represents a significant material stock at known locations and quantities. It is an important asset for the UK and allows potential component and material harvesting post-usage.

After the ramp up in use at the beginning of the millenium, the first wind turbines are currently reaching their orignially designed end-of-use time of about 20 years. This is likely to increase in the near future. The need for actively entering into circular economy revalorisation phases for these wind turbines comprises:

- prolongation of usage by refurbishment and revamping etc., including potential upgrades

- improving material recovery by dedicated decommissioning, including component harvesting and material recycling

Future demand for wind turbines

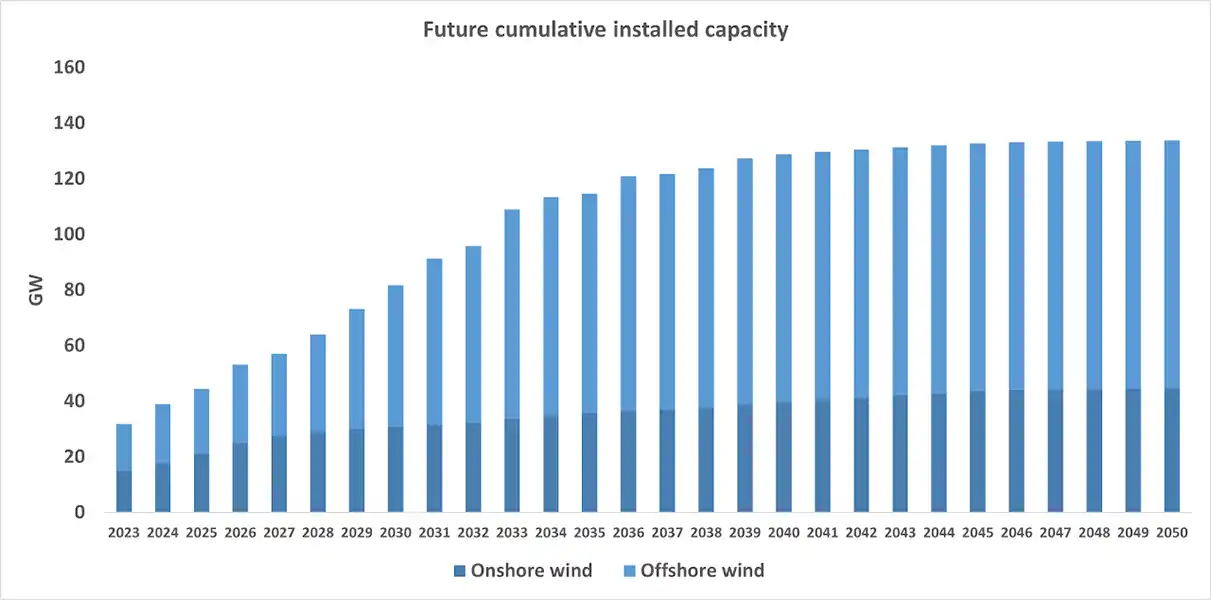

According to the National Grid (2022), the UK will have 224.65 TWh offshore and 85.40 TWh onshore wind power electricity generation and 50.95 GW offshore and 30.77 GW onshore installed capacity in 2030. It is estimated that the contribution of wind turbines to the energy mix will reach 549.8 TWh by 2050, of which onshore is likely to provide 151.5 TWh and offshore 398.3 TWh. With an expected 133.8 GW of total installed wind turbine capacity (89.06 GW offshore; 44.77 GW onshore), the number of wind turbine installations will continue to grow over the next 27 years.

Materials, techonologies and composition

Most of the wind turbines in the UK are still operating. The overall lifetime of wind turbines is expected to be between 20 and 30 years. Wind power technology transformations and expanding the size of wind turbines to increase efficiency have both led to the use of different types of generators and the increasing amount of materials used in wind turbines.

Evolution of wind turbine size

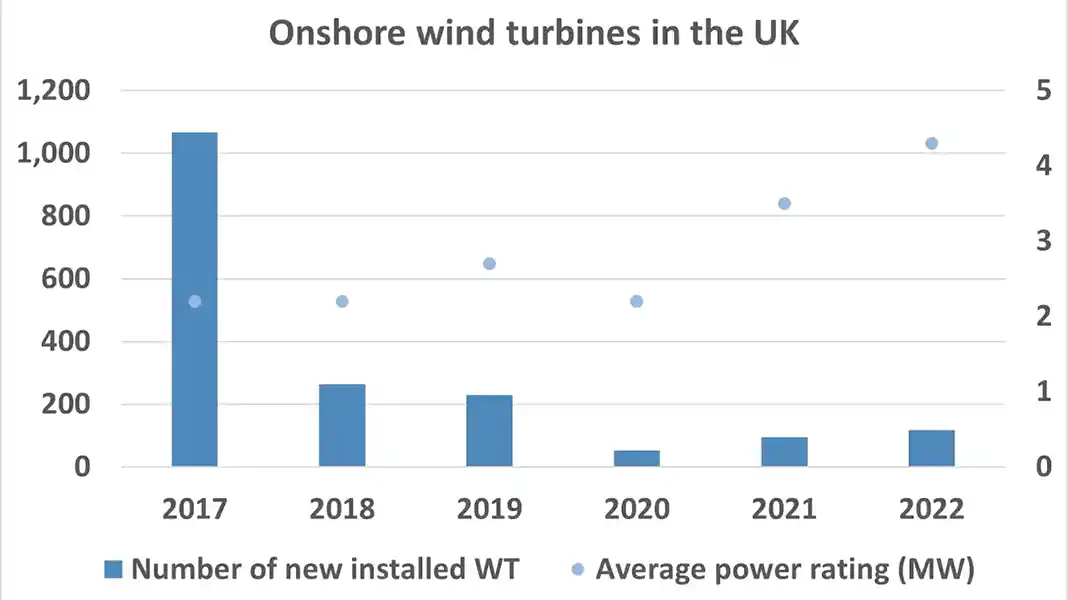

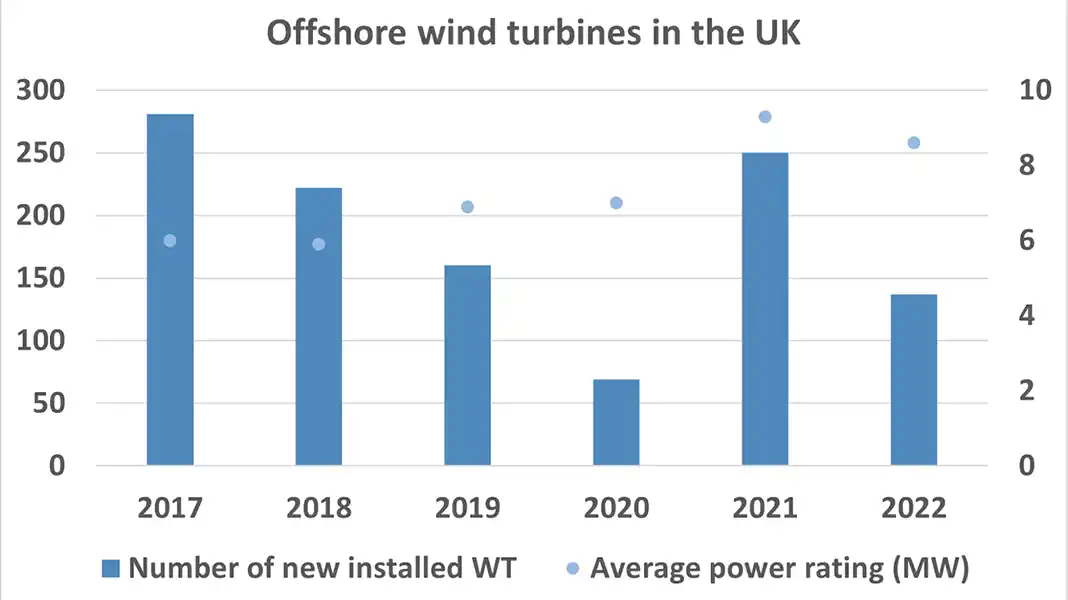

The size of wind turbines (in terms of rotor diameter, hub height and rated power) has increased dramatically in the past two decades. Figure 5 shows the evolution of UK offshore wind turbines' size from 2002 to 2022 to 2023. Figures 6 and 7 show the number of newly installed wind turbines and the average power rating of onshore and offshore wind turbines between 2017 and 2022. The onshore wind turbines had an average power rating of 4.3 MW, whilst the offshore wind turbines had an average power rating of 8.6 MW in 2022.

Types of generators

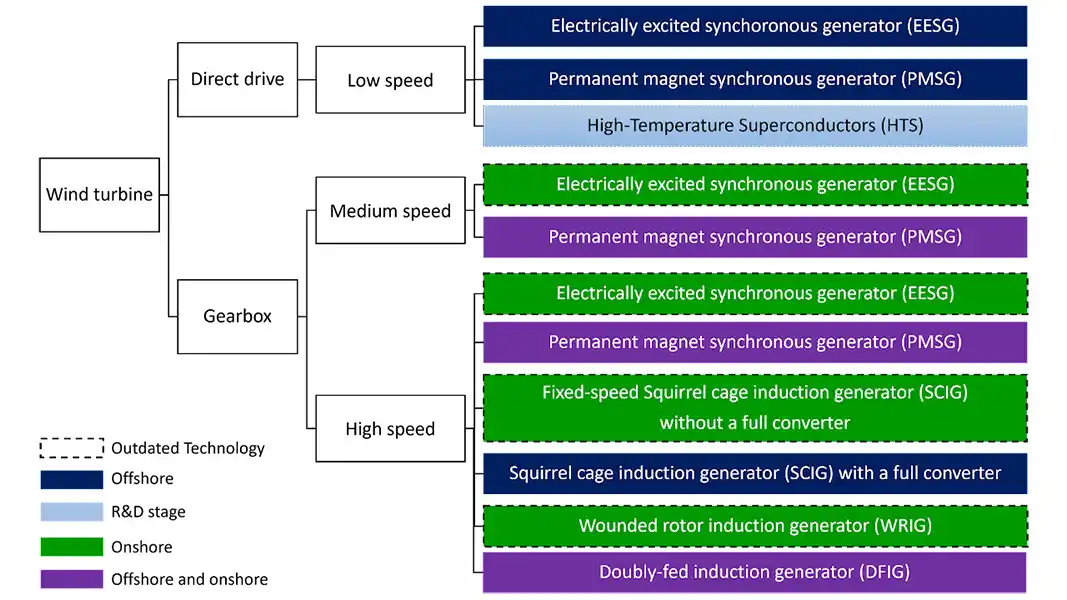

The generator is the key component of wind turbines and there are different types of generators. The transmission is typically classified into direct-drive and gearbox mechanisms, with different machine types, rotors and speeds. Classification into different subtechnologies with typically dedicated materials and component configurations provides an opportunity to estimate future release rates and the current composition of the material stock in use.

The types of wind turbines can further be classified based on the drivetrain configuration, speed and onshore and offshore application.

The black dashed lines in Figure 8 represent the types of generators that were widely adopted in the past decade, but no longer dominate the market. Conventional generators (for example, squirrel cage inductor generators (SCIGs) or wound rotor induction generators (WRIGs)) that were developed before permanent magnet synchronous generators (PMSGs) do not include permanent magnets and tend to be used in onshore wind turbines rather than offshore installations.

Doubly fed induction generators (DFIGs) currently have a higher market share but are only used for less than 3 MW capacity, while the penetration rate of PMSGs has continuously been increasing due to their better energy efficiency.

PMSGs are currently the main research and development focus of all generator types regarding reducing cost and REE content whilst increasing turbine capacity and efficiency. Direct drives based on high-temperature superconductors (HTS) are a new type of generator at the research and development stage and could potentially be used in the future to reduce the use of REEs.

Translation into material stocks

A typical wind turbine consists roughly of:

- 234 500 to 413 000 kg/MW concrete

- 107 000 to 132 000 kg/MW steel

- 950 to 5000 kg/MW copper

- 500 to 1600 kg/MW aluminium

- 12 to 180 kg/MW neodymium

- 2 to 17 kg/MW dysprosium

- 0 to 35 kg/MW praseodymium

- 0 to 7 kg/MW terbium

Whilst small in volume, REEs embedded in the magnets, which are largely installed in the generator but are also found in the motors for navigating the pitch and dirction of the blades, are a crictial enabler to deliver the required reliability and performance of the wind turbine.

More information

References

National Grid. 2021. Future Energy Scenarios 2021.

National Grid. 2022. Future Energy Scenarios 2022.

UK Government. 2020. UK Government Offshore Wind Sector Deal.

Futher reading

Carrara, S, Alves Dias, P, Plazzotta, B, and Pavel, C. 2020. Raw materials demand for wind and solar PV technologies in the transition towards a decarbonised energy system. (Luxembourg: Publications Office of the European Union.) ISBN: 978-92-76-16225-4 DOI: 10.2760/160859

National Statistics: Digest of UK Energy Statistics (DUKES): renewable sources of energy

Offshore Renewable Energy Catapult https://ore.catapult.org.uk/

Renewable UK: wind energy statistics

Serrano-González, J, and Lacal-Arántegui, R. 2016. Technological evolution of onshore wind turbines — a market-based analysis. Wind Energy, Vol. 19, 2171‐2187. DOI: 10.1002/we.1974