Urban mining is the process of reclaiming compounds and elements from any kind of anthropogenic (human made) stocks, inlcuding buildings, infrastructure, industries, products (in and out of use) and environmental media receiving anthropogenic emissions (Cossu and Williams, 2015). Examples include, but are not limited to:

- electronic waste (e-waste)

- municipal waste

- construction waste

- tyres

The stocks of these materials may represent an important resource, with the concentration of some elements generally being comparable to, or even exceeding, natural ores (Cossu and Williams, 2015). For example:

- the average gold content of waste electrical and electronic equipment (WEEE) is almost 130 ppm, compared to an average of 1 ppm in natural ores

- similary, the figures for silver are 1000 ppm in WEEE versus 215 ppm in ores

- the same is true of palladium: 52 ppm in WEEE versus 3 ppm in ores

(Figures from Tesfaye et al., 2017)

Future potential

There is significant potential to recover metals from e-waste, especially from consumer electronics such as mobile phones. These products often contain a raft of precious (gold; silver; palladium), base (copper; zinc) and critical (indium; rare earth elements; lithium; cobalt) metals.

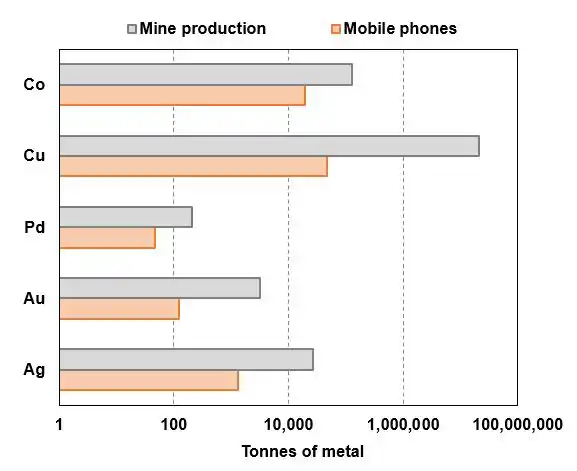

Figure 1 shows the average content of cobalt, copper, palladium, silver and gold in the global mobile phone stock in 2020 (around 5.2 billion units) compared to mine production, with some of the metal volumes not being insignificant. For exmaple, contained palladium is about 200 tonnes, or almost one quarter (24 per cent) of global mine production.

Although the potential to recover valuable metals from e-waste is significant, there are challenges that must be overcome related to effective collection, separation and processing. The collection of e-waste is a signifcant barrier to recycling that will require government policy intervention and public education to fix (Tesfaye et al., 2017). There are technical challenges related to processing, as e-waste constitutes an increadibly diverse feedstock with varying product designs that have variable metal contents. This can make processing difficult.

One possible route for processing is pyrometallurgy, a high-temperature process copes well with varied feedstocks. However, volatile metals such as indium, gallium and lithium are likely to be lost to the waste stream through slag. Hydrometallurgy is another option for processing e-waste; it is more selective and can be engineered to capture most metals. It can, however, be expensive and time consuming to install compared to pyrometallurgical methods. Irrespective of the route chosen, both require careful environmental management.

More information

References

Cossu, R, and Williams, I D. 2015. Urban mining: concepts, terminology, challenges. Waste Management, Vol. 45, 1–3. DOI: 10.1016/j.wasman.2015.09.040

Tesfaye, F, Lindberg, D, Hamuyuni, J, Taskinen, P, and Hupa, L. 2017. Improving urban mining practices for optimal recovery of resources from e-waste. Minerals Engineering, Vol. 111, 209–221. DOI: 10.1016/j.mineng.2017.06.018