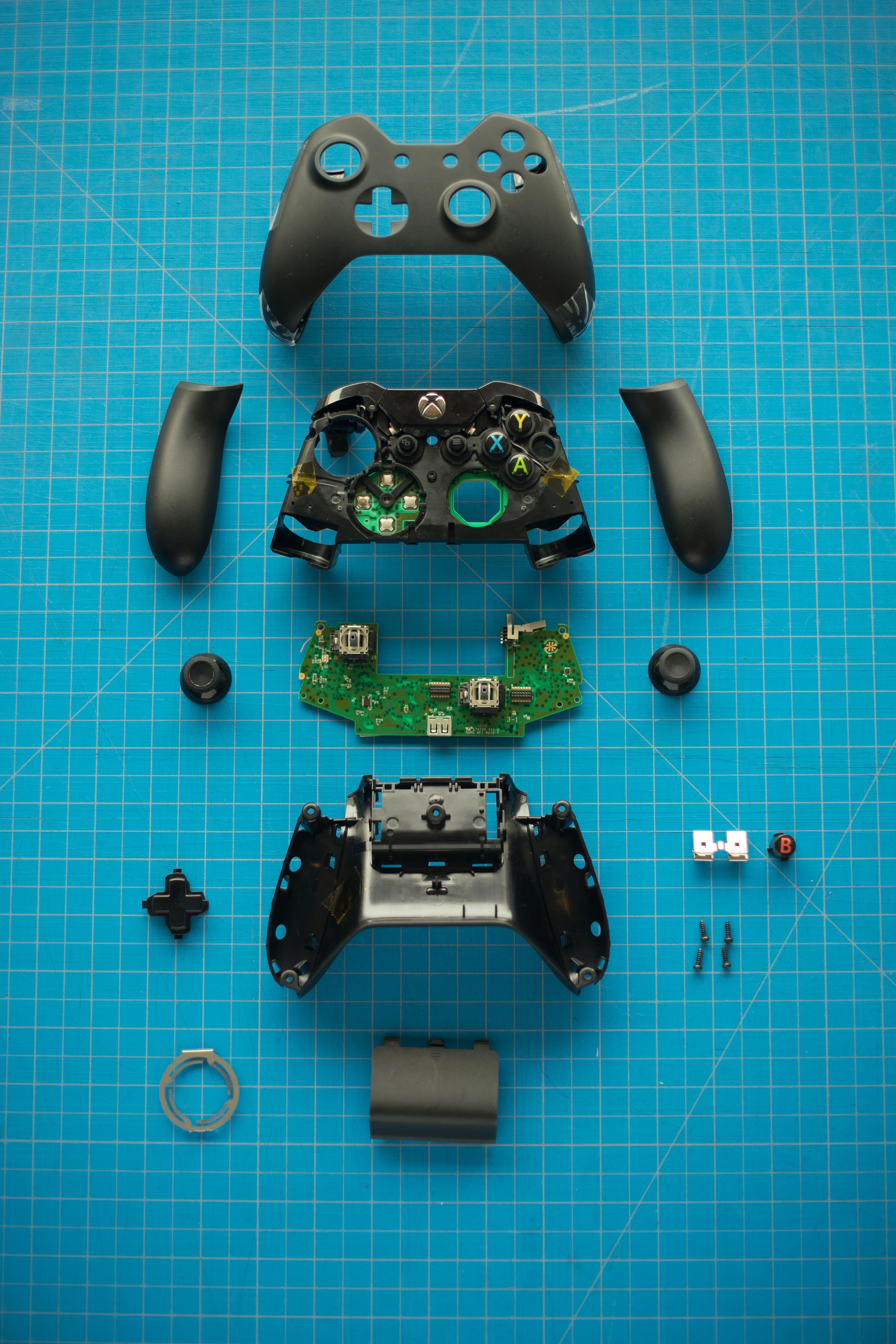

Remanufacturing is the process by which a product is disassembled and rebuilt, basically creating a new products. Remanufacturing involves the dissassembly, repair and replacement of worn-out or obsolete components. It involves quality and inspection checks that mimic the initial product manufacture.

Remanufacturing is commonly more costly than refurbishemnt, because it delivers an end product of a higher standard. For example, electric vehicle lithium-ion batteries can be remanufactured, if their health and original design allow for easy disassembly to enable access to specific components (for example, individual cells) and use in the production of new battery packs with reduced environmental footprint.