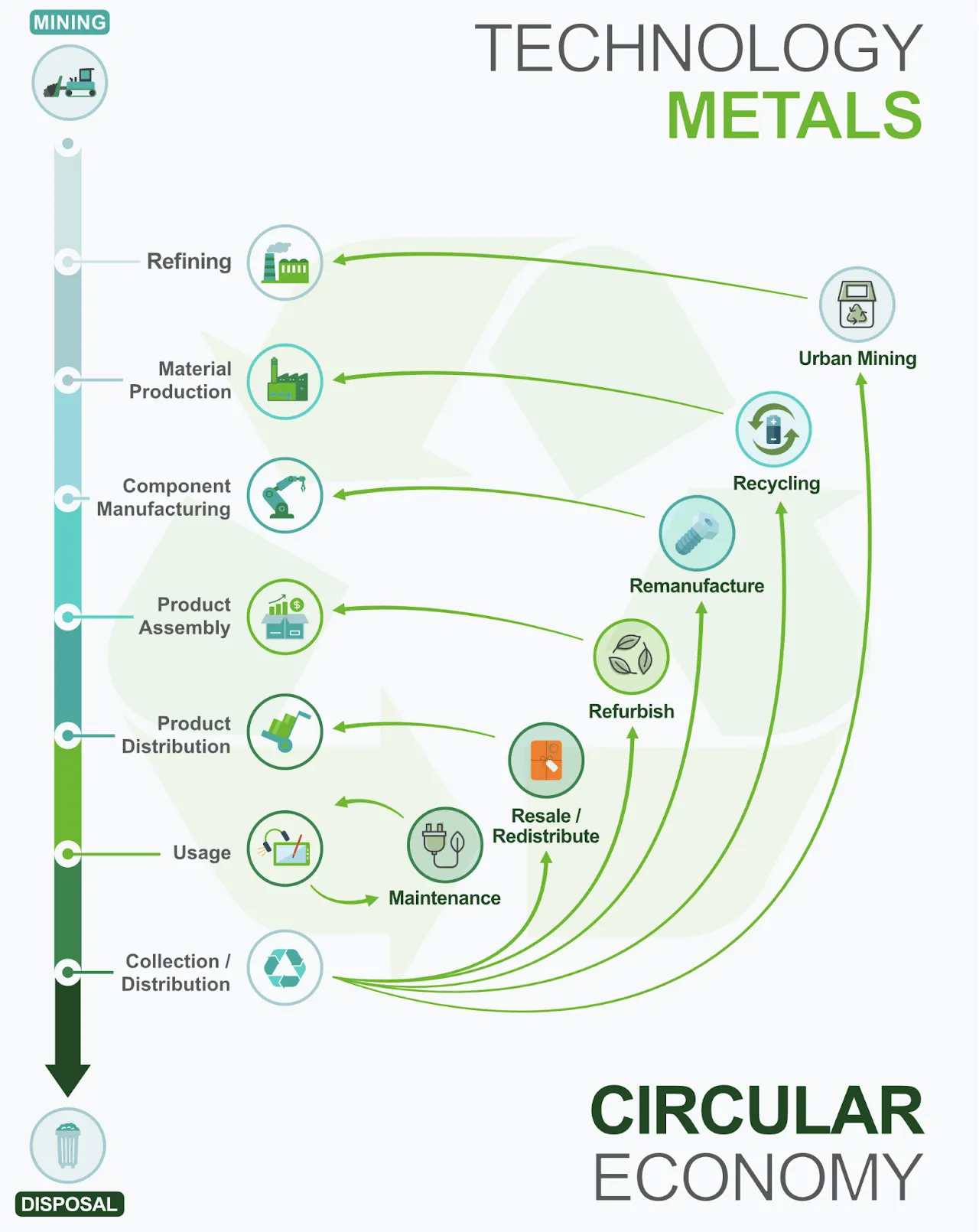

Technology metals are finite resources and their demand is expected to increase significantly in the near-term. The production of primary and secondary technology metals is essential to ensure security of supply. The development of a circular economy for technology metals has an important role to play in that, as well as in improving material and energy efficiency, and ensuring that secondary resources are kept at their highest value within the UK. Although recycling has the potential to substitute primary material input, it cannot on its own solve the supply bottleneck. Whole material system optimisation and the development of circular and reverse flows is essential to create sustainable value chains.

- At the product level, used products can be reused or resold on second-hand markets

- At the component level, end-of-life products are collected and dismantled, so that the used components can be refurbished or remanufactured to become components in new products

- At the material level, end-of-life products and components can be treated through different recycling processes to become the secondary supply for new product manufacturing

Implementing these circular economy strategies can help to bring end-of-life resources back into the system to increase material efficiencies, reduce primary material consumption, prevent waste generation and reduce material losses.

Opportunities for circularity

The reverse options along the value chain of technology metals include re-use and re-sale, repair and maintenance, remanufacturing, refurbishing and recycling. The concept and practice of urban mining for technology metals should also be considered.