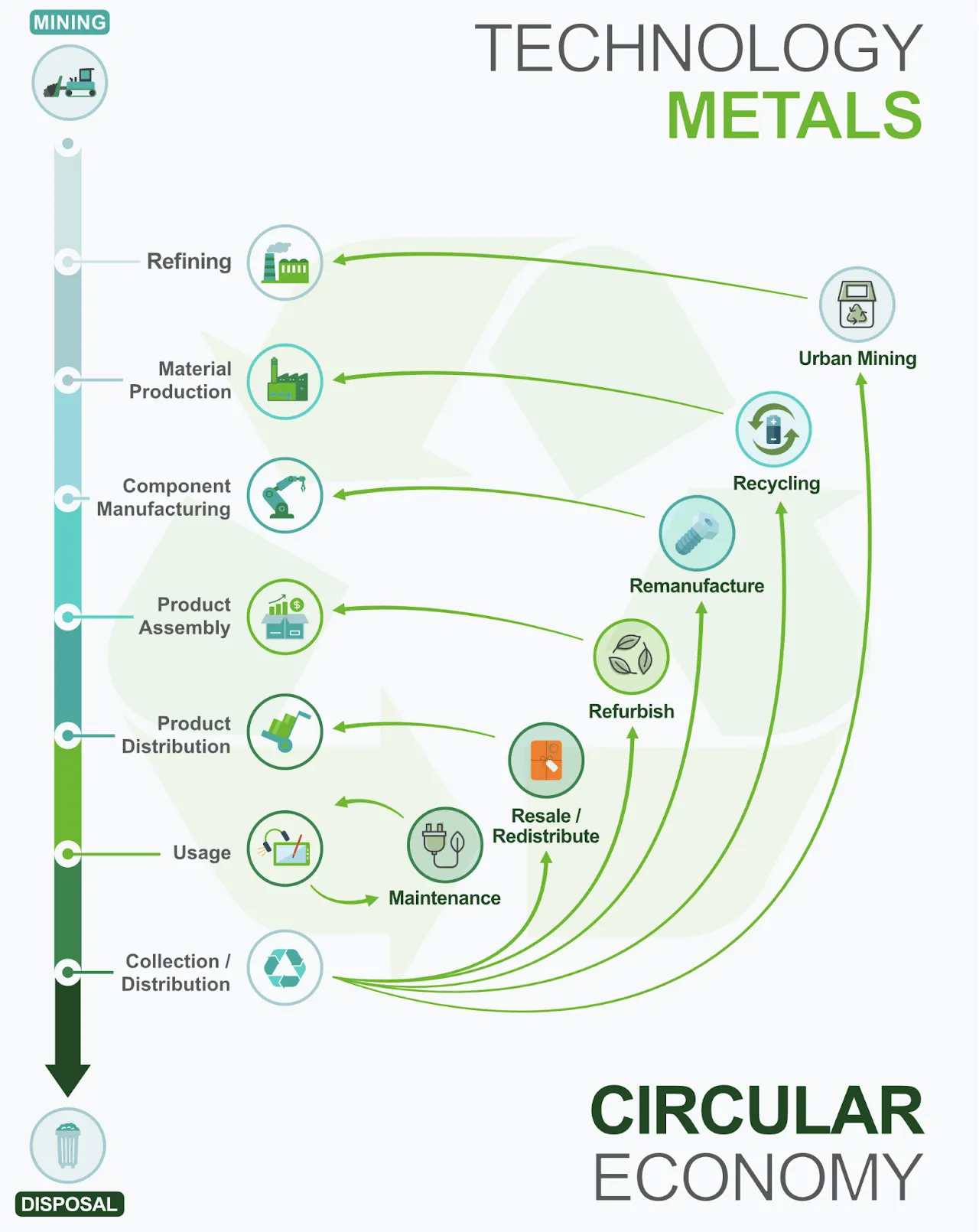

Circular product cycles allow the improvement of material, component and product yield, decouple virgin material use and reduce the energy consumption and emissions associated with material extraction and processing.

Circular flows

Improving the yield of materials, components and products requires a full system view and the identification of revalorisation options that will keep materials, components and products in use, at their highest level of aggregation, for as long as possible.

We introduce an holistic circular economy framework for describing the different options to boost material, component and product yield with reference made to our signature applications: electric vehicles and wind turbines.

More about circular flows

Circular interventions

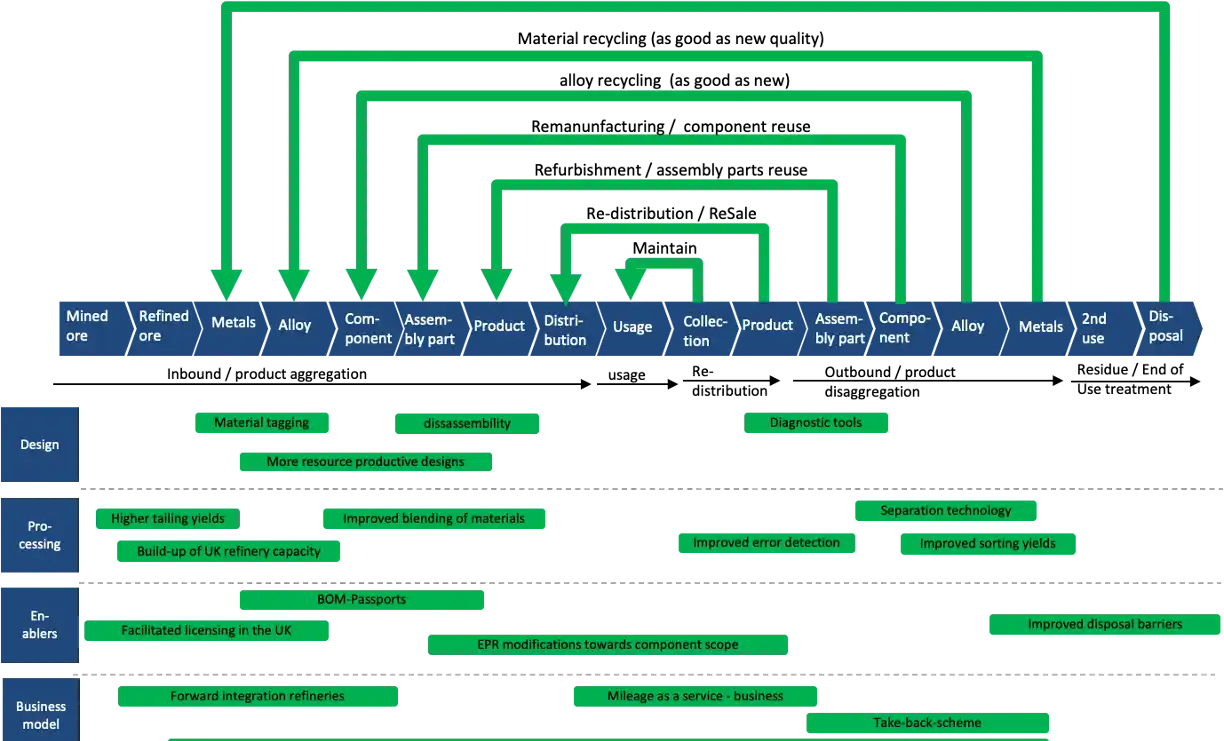

In order to migrate a linear economic value chain to a more circular configuration, a number of interventions are required with a coordinated implementation. The objective of these interventions is to change the physical flow of materials, components and products towards higher degrees of cirularity by maintaining their status at the highest level of quality within the system for as long as possible.

To improve the circularity of materials, components and products over their respective usage cycle, a number of 'levers' typically need to be integrated into a circular economy programme. These levers commonly fall into one of the following categories.

- Design: improves resource usage per unit of service (for example, improving material mix) and facilitates revalorsiation along the future usage cycles (for example, disassembly or separation)

- Processing: allows efficiency, effectivenes and sustainability of the linear and the reverse loops to be improved (for example, improving recycling yield via new technologies for material extraction post-usage)

- Enablers: reduce the transaction cost or improve the ease of pursuing more inner circles, which typically exhibit higher potential to keep materials longer and at higher level of quality in use (for example, material tagging)

- Business models: aim to improve the economic potential of (private sector) actors to choose more circular configurations over the classical make–take–dispose linear value chains (for example, reaping return of investing in durability of products by moving away from a sales-based to a performance-based commercial model)