In a survey conducted by Consumer Reports, laptop owners reported that they expected their computers to last five years, yet, as was discovered recently in a survey of more than 58 000 subscribers who purchased laptops between 2010 and 2015, almost one in five of those computers will experience some kind of breakdown in the first three years.

In this section we will share our observations on the challenges of boosting circularity.

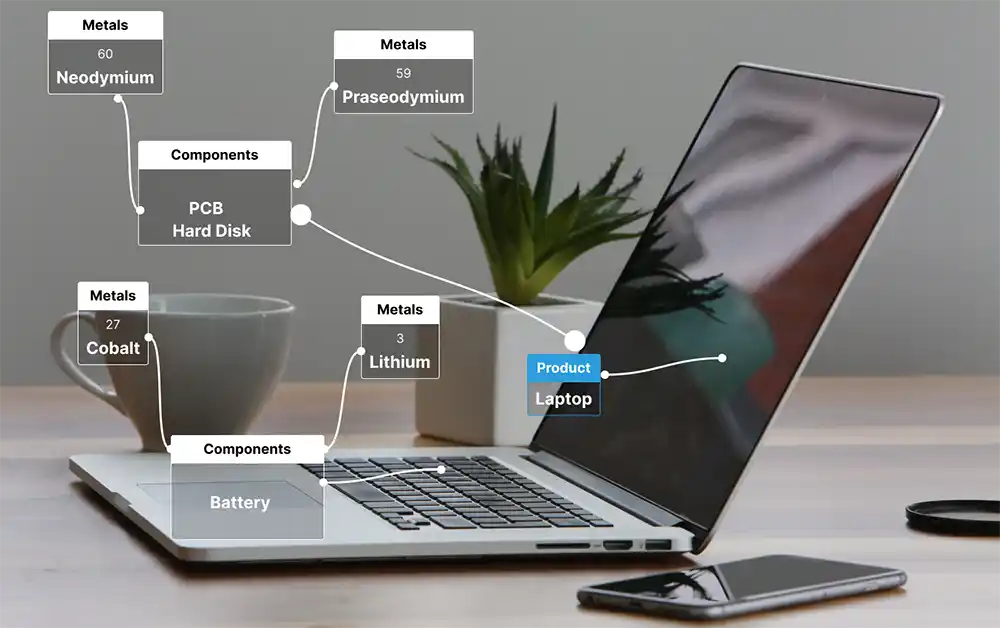

Components and metals in laptops

Supply and demand

Five billion people around the world use the internet everyday, 67 per cent of whom do so on a laptop. The global laptop market was worth US$165.3 billion in 2021 and is expected to continue to grow at a steady 4 per cent compound annual growth rate until 2027.

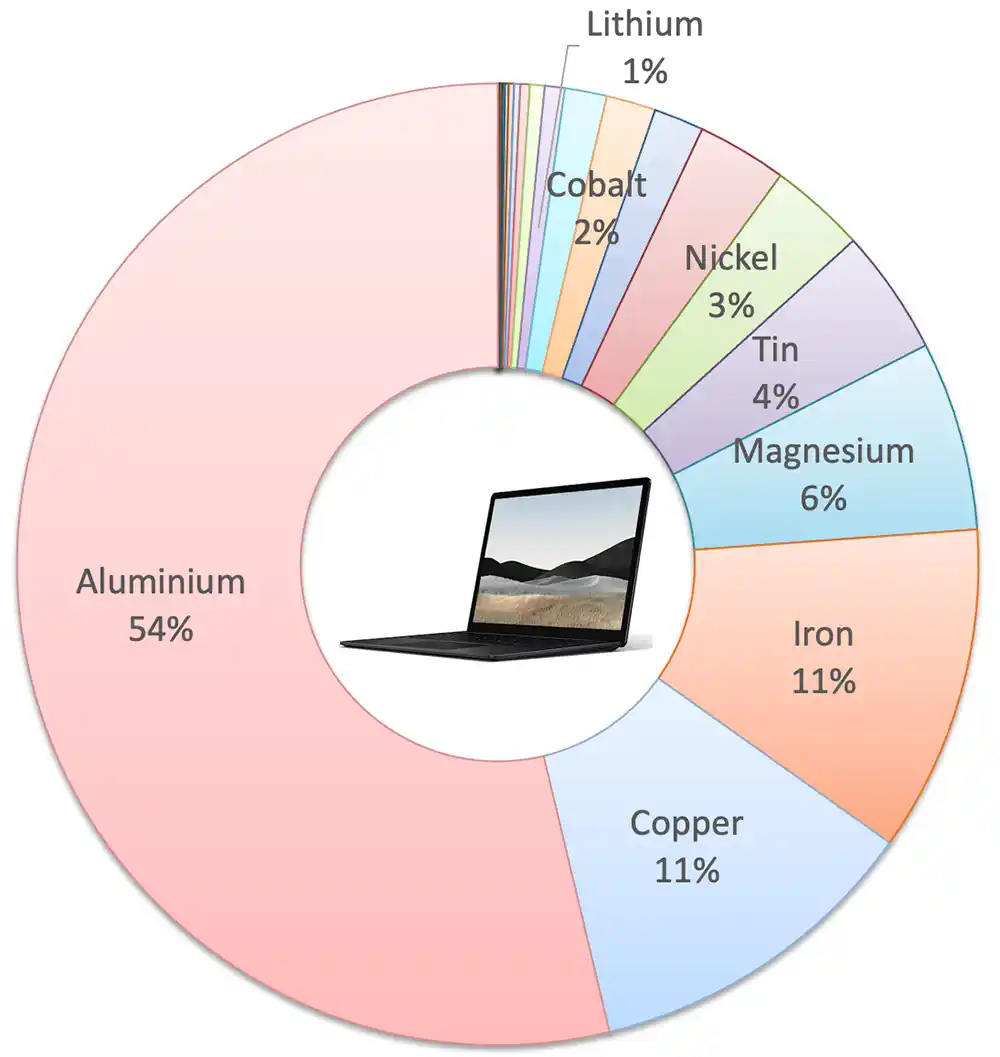

Laptop materials

A typical laptop contains more than 240 substances. The chart and table provided in Figure 3 illustrate the mass substances in a typical laptop, comprising a cumulative concentration of nearly 99 per cent.

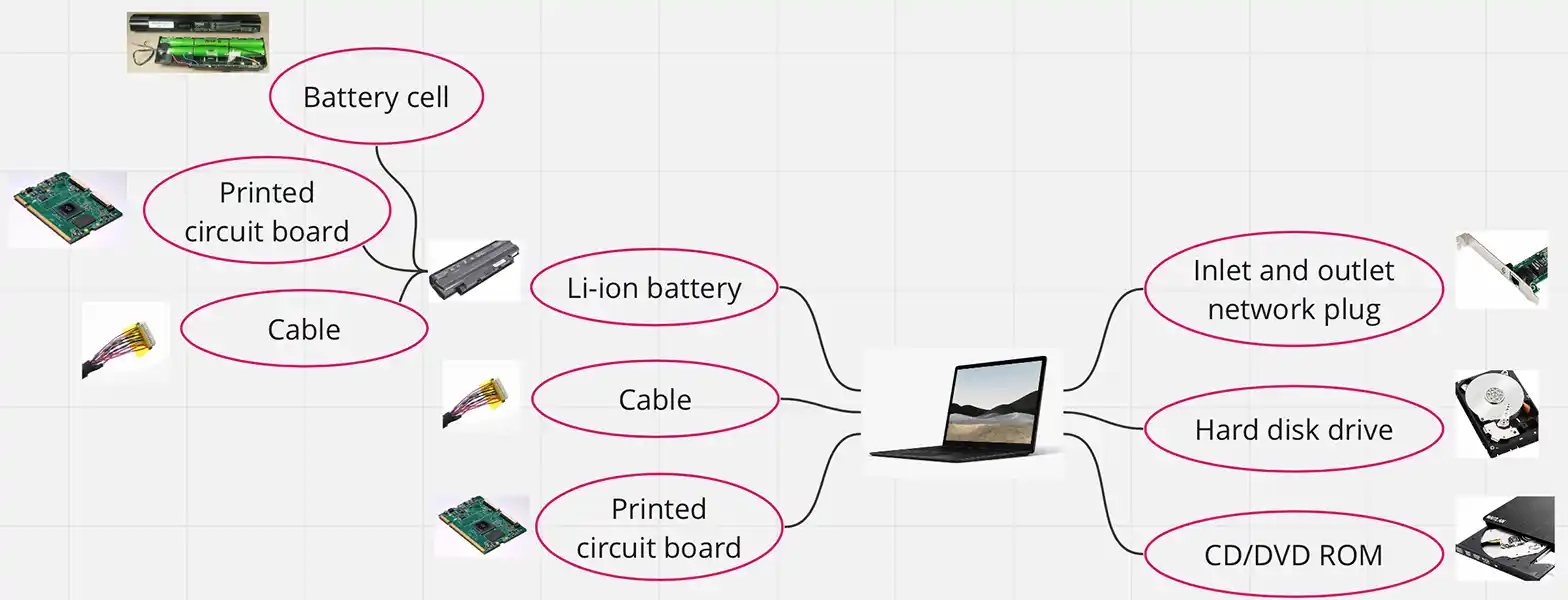

Substances and components of a laptop

The general structure of a laptop comprises a few standard components like the lithium-ion battery, which supports power generating and can be further broken down into battery cell, printed circuit board and so on, whilst parts of the hard disk drive contain rare earth element magnets.

Material stocks

A typical laptop consists of:

- aluminium: 54 per cent

- copper: 11 per cent

- iron: 11 per cent

- magnesium: 6 per cent

- tin: 4 per cent

- nickel: 3 per cent

- cobalt: 2 per cent

- lithium: 1% per cent

Lithium and cobalt are embedded in battery cells. Learn more about lithium, cobalt, or rare earth elements.

Contact

For questions regarding the UK Technology Metals Observatory, please contact Dr Evi Petavratzi.